- Home /

- Hygiene Engineering /

- Sterile drainage system

Sterile Drainage System

Hygienically Engineered Stainless Steel Drainage System

Avismatic, a leader in designing and implementing stainless steel drainage systems, understands the pivotal role drainage plays in industrial food preparation. Guided by its HygieneFirst philosophy, Avismatic delivers intelligent drainage solutions that prioritize hygiene, enhance food safety, and reduce operational costs.

Poorly designed drainage systems result in unhygienic spaces, bad odour, possible contamination, compromise hygiene standards and product safety. Late detection results in high maintenance costs, and compliance checks threatening facility operations and business viability. Avismatic addresses these challenges by engineering sustainable, integrated drainage systems that protect businesses, public health, and the environment.

Manufactured from high-quality austenitic stainless steel (grades 1.4301 or 1.4404 per EN 10088), Avismatic systems meet the rigorous demands of food processing, dairy, breweries, commercial kitchens, and pharmaceuticals. By improving hygiene and functional performance, Avismatic sets a new standard in drainage, ensuring unparalleled reliability and safety across industries.

Avismatic’s Hygienic Drainage System covers following different categories:

Point Drainage

Small Drain Traps in square and circular shape with drain baskets

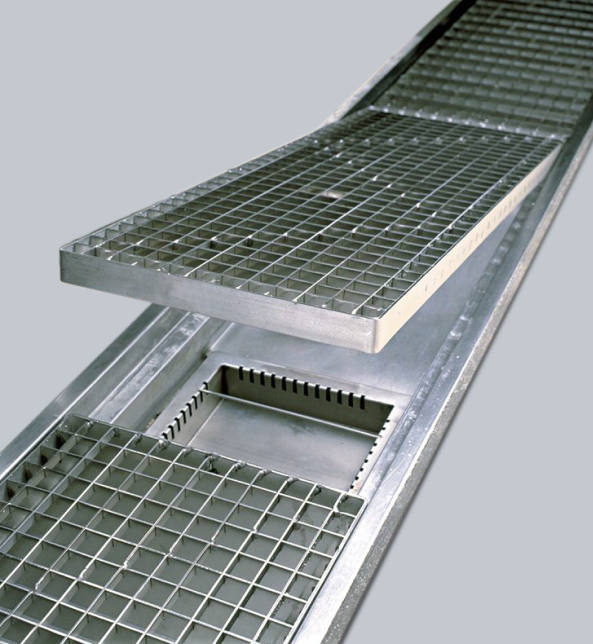

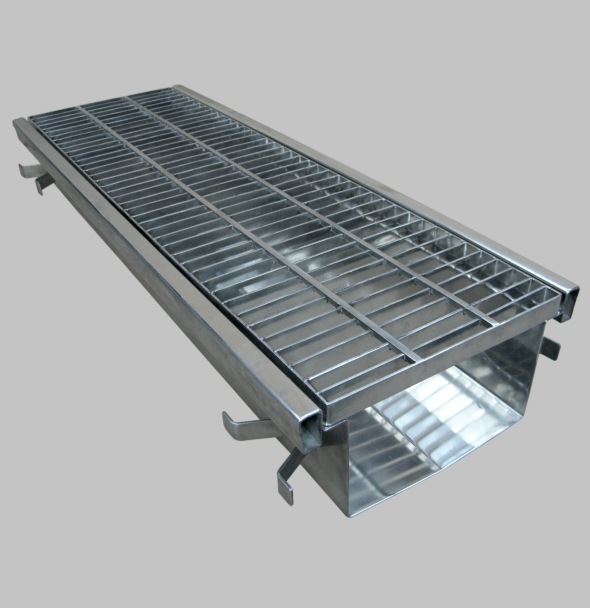

Linear Drainage

Linear drain channel/gullies with covers.

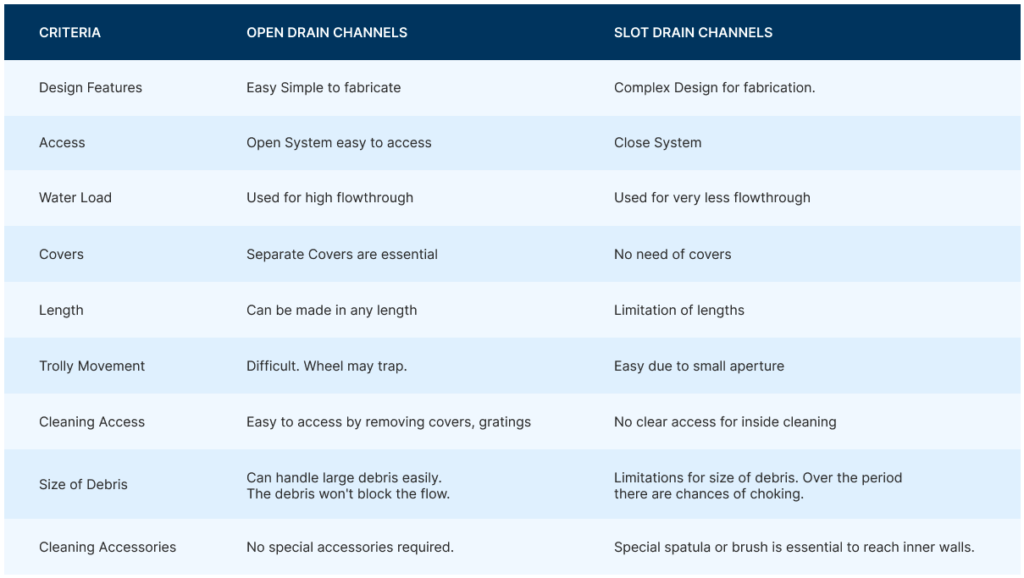

The selection of type of Linear Drainage is influenced by various factors such as quantum of water load, frequency of washing cycles, size of debris, floor area, access to the drainage system, mechanical load on the drains by way of trolley or other material movement, retention capacity, flowrate and ability to drain continuously, hygiene requirements, etc.

We can broadly compare the Open Drain Channels

with Slot Drain Channels as under: