- Home /

- Conveying Equipments /

- Conveyor /

- Belt Conveyor

Belt Conveyor

Avismatic’s Conveying Solutions

The range of Conveying systems offered by Avismatic includes straight transfers, radius conveyors, elevators, multilane systems, and hygienic options. By prioritizing specific customer requirements, Avismatic ensures a seamless, value-added service from concept to commissioning, delivering efficient and effective solutions for various applications.

Conveyor Solutions that cover all functions

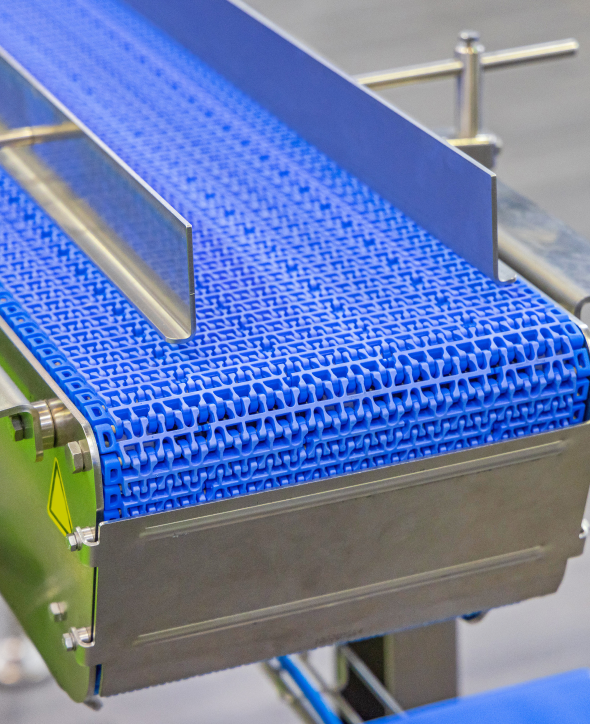

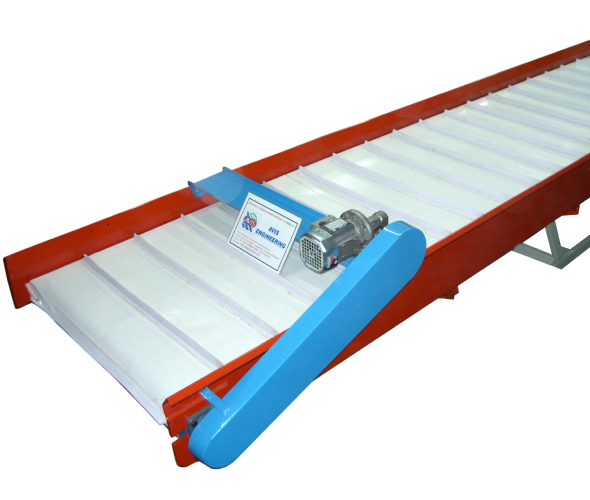

PU, PVC, MPB Belt Conveyors

Gooseneck Elevators

Avismatic’s Gooseneck Elevators is designed for delicate handling of fragile products like potato chips and tortillas, ensuring gentle transport at elevated heights. The signature swan-neck shape prevents breakage and maintains seasoning integrity during the transfer from flavoring to packing. Fitted with modular plastic belts and bucket-like scoop-flights, it ensures secure product handling even at 90° angles. For enhanced hygiene, these elevators can also feature thermoplastic positive drive belts, offering a smooth, crevice-free surface that is easy to clean and minimizes bacterial growth.

Stainless Steel Belt Conveyors

The belt is made of imported special grade Stainless Steel. Ultra-hygienic systems ideal for heating, cooling, frying, and cooking, pelletizing, etc. offering exceptional longevity.

Metal Detector Conveyors

As the name suggests, these highly specialised conveyors are designed to detect any miniscule ferrous or non-ferrous metal particles in the naked or packed product. The conveyor is fitted with a product-suitable accessory to reject the product contaminated with metallic particles.